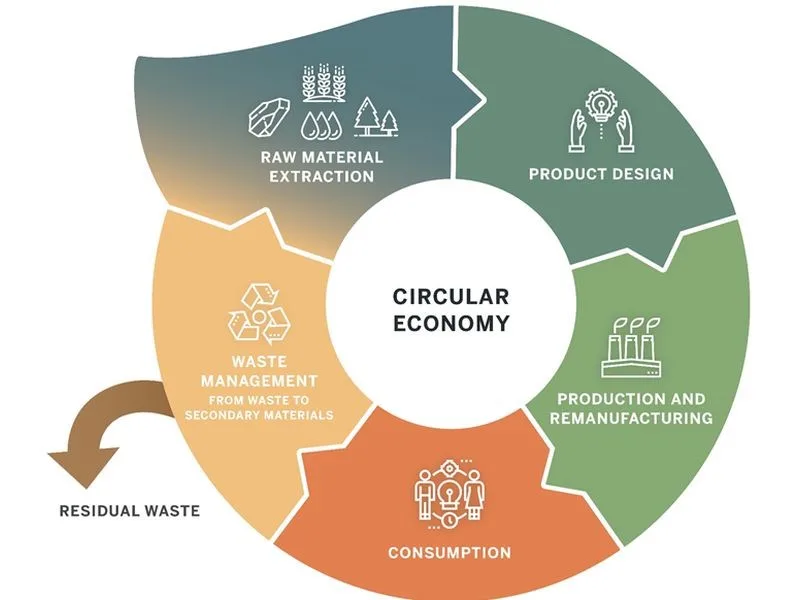

The circular economy redesigns buildings as long-lasting systems where materials are used at their highest value and waste is eliminated from the outset through design. From this perspective, architecture is not a single-use product. It is a material ecosystem that recirculates components through maintenance, repair, reuse, remanufacturing, and finally recycling, while also restoring nature. This framework stems from widely accepted definitions and has been adapted to the built environment due to construction’s high resource consumption and significant production of carbon and waste.

The direction is clear in global policy and standards. The European Union’s Circular Economy Action Plan and Level(s) framework promote life-cycle thinking and common indicators for buildings. Professional standards such as the RICS Whole Life Carbon Assessment make it practical to account for impacts from the product stage to the end of its life. Together, these define what it means for a project to be circular in measurable and comparable terms.

Introduction to Circular Economy in Architecture

Adopting a circular approach is crucial because the construction sector impacts the climate, biodiversity, and resource security. Analyses show that circular strategies that reduce demand for carbon-intensive materials such as steel, aluminum, cement, and plastic could significantly reduce global CO₂ emissions from construction materials by mid-century. This can be achieved by using less material overall, substituting with renewable or reused materials, and reusing products.

Frames are now translating this concept into daily design and briefings. Level(s) provides a common language for performance from the early design stage to the end-of-life stage, while the RICS guide incorporates lifetime carbon thinking into cost and design decisions. This shifts circularity from being a goal to a verifiable and comparable set of building, facade, equipment, and supply options.

Defining the concept of circular economy for the built environment

Circular economy in buildings means designing assets to ensure materials circulate at high value for as long as possible. This involves selecting systems that can be maintained, spaces that can be adapted for new uses, and assemblies that can be dismantled without damage. The goal is to prevent waste, keep components in use, and renew the natural systems that provide these materials.

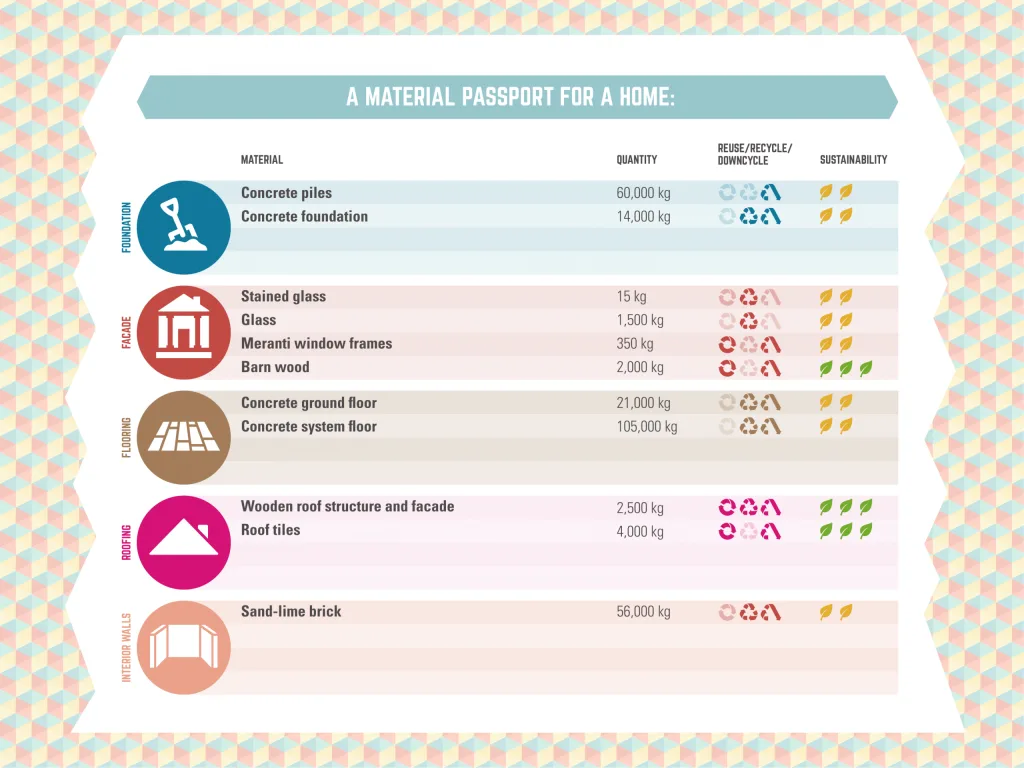

This concept is supported by tools such as material passports and recyclable building design. Material passports document what is in a building and how it can be recovered later. Recyclable design sets rules for connections, layering, and access, so that elements can be removed and reconfigured. These ideas have been developed and implemented through the EU’s Buildings as Material Banks initiative.

A frequently cited example is the wooden headquarters of Triodos Bank in the Netherlands. This building was designed as a demountable structure and equipped with a detailed material passport, enabling it to be dismantled into its components and reused. This example demonstrates what a circular building could look like when the concept is applied to the structure, detailing, and documentation.

Basic principles: reduce, reuse, recycle, renew

Reduction

The primary goal is to use fewer resources. Architects achieve this by correctly sizing the area and structure, selecting efficient openings, and preserving existing buildings whenever possible. Reducing the demand for raw steel, cement, aluminum, and plastic provides a significant carbon benefit on the sector’s material footprint.

Reuse

Keeping components in use preserves embodied carbon and generally reduces costs and risks. Reuse thrives when there are marketplaces and protocols for quality and insurance. European actors such as Rotor Deconstruction demonstrate how doors, ceilings, plumbing, and facades can be recovered on a large scale and returned to projects.

https://www.wbdm.be/en/news/rotor

Recycling

Recycling is valuable, but it is a lower-value cycle than reuse because materials are typically converted into lower-quality products. Circular design treats recycling as a last resort after design for maintenance, repair, refurbishment, and direct component reuse. Standards and assessments that follow life cycle stages help teams understand when recycling is appropriate.

Renewal

Circularity is not just about cycles. It also involves restoring ecosystems that provide building materials. Responsible use of renewable bio-based materials and nature-conscious design support this goal. Authoritative definitions treat renewal as a fundamental principle alongside waste elimination and material circulation.

The difference from linear development models

Linear construction follows the build-use-dispose model. Raw materials are extracted, products are built, and at the end of their service life, the assets are demolished and sent to a landfill. Circular construction replaces this with a system that eliminates waste, keeps products and materials in circulation at their highest value, and regenerates natural systems. This is not just a series of recycling tactics, but a different economic model.

Because it has a systemic structure, it is dependent on a circular construction life cycle assessment and verification. All life cycle carbon methods quantitatively measure the impacts during the product, construction, use, and end-of-life stages. Design standards such as ISO 20887 formalize dismantling and adaptability strategies, so that differences from linear applications are reflected in drawings, specifications, and contracts.

Importance for architects and stakeholders

Circular thinking for architects expands the scope. The program evolves into an adaptable use over time. Details become reversible connections. Specifications become inventories with end-of-life pathways. Policy and market tools help. Level(s) aligns customers, designers, and contractors on indicators while enabling the joint assessment of full life-cycle carbon standards, cost, and carbon.

For customers, contractors, and operators, circularity means risk management and value creation. Buildings designed for future changes can be reconfigured rather than replaced with new ones. Passported components become recoverable and tradable assets. Examples such as the Triodos Bank headquarters demonstrate how material banking and demountable timber structures can support a business model that combines design purpose with future recovery value.

Design Strategies for Circular Buildings

Circular buildings are designed as living systems. Their components can be repaired, reconfigured, and ultimately recovered without losing value. This mindset is formalized through standards and frameworks that guide decisions from early briefings to end-of-life decisions, ensuring that circularity is not just a slogan but a measurable design outcome.

Design for disassembly and dismantling

Dismantling-friendly design is the practice of detailing structures, coatings, and interiors to enable clean dismantling. This practice favors mechanical fasteners over destructive adhesives, open access to fasteners, and legible layering of components. The international reference is the ISO 20887 standard, which establishes principles for both disassembly and adaptability and links them to verifiable design choices.

Policies and guidelines now incorporate this concept into project delivery. The EU Level(s) framework includes design indicators for disassembly and recycling, providing teams with a common language to evaluate assemblies that can be safely disassembled and reused. This translates qualitative intent into comparable evidence across projects.

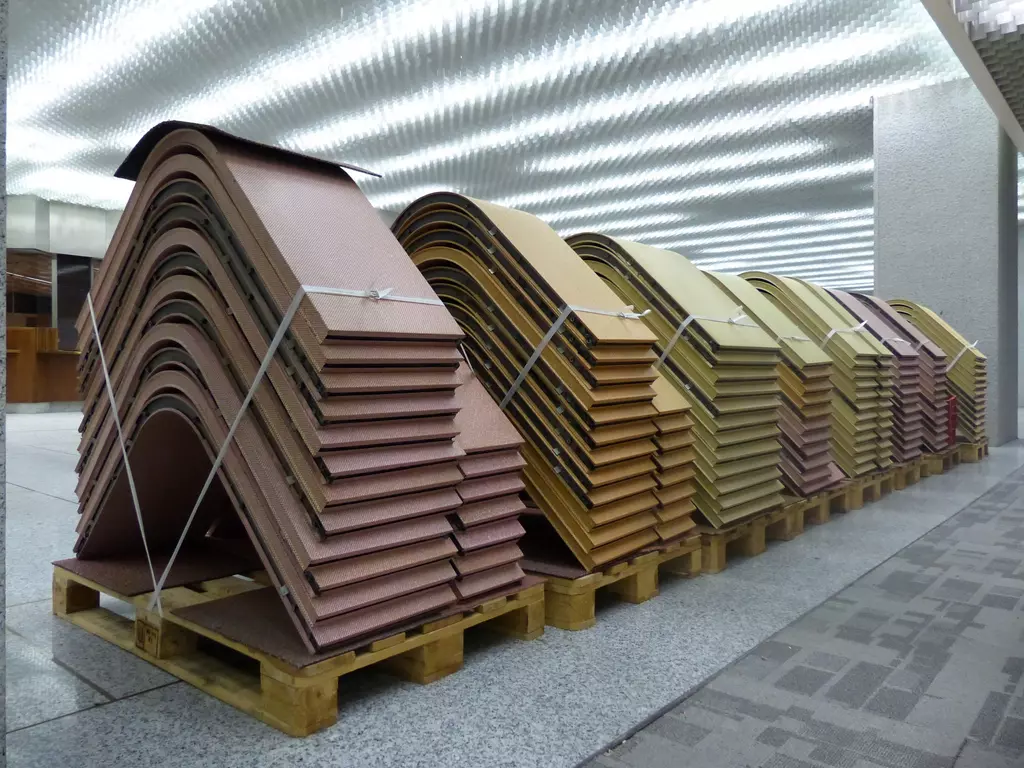

Examples demonstrate the scaled-up version of this concept. The Triodos Bank headquarters in the Netherlands was designed as a demountable wooden office with components documented for future recycling. The Circle House program in Denmark demonstrates that reversibility can coexist with standard construction methods by offering residential prototypes in which up to 90% of the materials can be reused at high value.

Modularity, adaptability, flexibility

Modularity reduces complexity by repeating a kit consisting of a limited number of parts. When modules share interfaces and dimensions, they can be changed, expanded, or reassembled over time. Level(s) promotes spatial arrangements and structural grids that anticipate change rather than resist it, encoding adaptability through design indicators for future renewal.

A strong case study is Circle House, which is based on the same six concrete elements for three housing typologies. The system speeds up construction and allows for later dismantling because every connection and tolerance is planned to be reusable. Thus, adaptability ceases to be a risk of demolition and becomes an asset strategy.

Embedded link

Paste the link to the content you want to display on your site.Embedded linkGöm

Get detailed information about embedded content↗

Unfortunately, this content could not be embedded.Please try againConvert to link

Standards link flexibility to technical details. ISO 20887 defines adaptability not as a default, but as a performance that must be designed. It emphasizes tactics such as increasing the size of service areas, separable layers for services and coatings, and reversible connections that accommodate future hardware.

Material selection and reuse potential

Selecting materials for a circular building means asking two questions at once. First, what is the current impact at the product stage? Second, what is tomorrow’s recovery path at the component and material level? Material passports answer the second question by recording information such as composition, fixation, location, and safe reuse pathways, enabling future teams to recover the value of components rather than sending them to waste.

Digital records reinforce this approach. Platforms such as Madaster treat buildings as material banks, tracking what has been installed and linking this to circularity indicators that predict reuse potential. This makes the asset’s hidden inventory visible to owners, insurers, and future projects that could repurchase components.

A growing reuse market completes the cycle. Rotor Deconstruction reduces the risk for design teams identifying large-scale reused elements by reliably supplying, classifying, and reselling recovered doors, ceilings, plumbing, and other coverings. Circular strategies transition from one-off pilot projects to standard procurement processes when such supply chains exist.

Life cycle thinking and pre-integration

The life cycle concept brings a holistic perspective to the early design stage. The building’s impacts are assessed throughout standardized stages, from product and construction to use and end-of-life phases. European standard EN 15978 defines these stages as A1 to A5, B1 to B7, and C1 to C4, and adds an optional D module for benefits beyond system boundaries. Using these categories aligns design choices with transparent carbon and resource accounting.

Integrating circular goals at the concept stage changes the summary. Level(s) encourages teams to set energy and comfort criteria as well as adaptability, renewal, and demolition targets, and then track these during the design and procurement phases. The result is a project where reversible details, modular systems, and documented materials are fundamental performance criteria from day one, rather than add-ons.

Project management should also reflect the same logic. Referencing ISO frameworks for disassembly and adaptability in the employer’s requirements creates clear responsibilities for interfaces, connection elements, and information transfer. Circularity becomes a delivery element included in the contract, not something that comes to mind later.

Material Systems and Technology Enablers

Circular architecture succeeds when materials are treated as long-term assets and data is transferred alongside products for decades. This requires reliable information, robust reuse markets, and digital workflows that make circular decisions visible to designers, customers, and regulators. Recent policy changes in Europe are accelerating this transition by standardizing how product data is created, verified, and shared throughout the supply chain.

A mature circular toolkit now encompasses passports for building components, open product identifiers for traceability, high-value secondary material flows, and digital assessments embedded in BIM. The result is a building that can be reconfigured according to standards that are verifiable, have proven performance through environmental declarations, and can be adapted as needs change.

Material passports and traceability systems

A material passport is a structured, digital record that details a building’s contents, the location of its components, how they are secured, and how they can be recovered or reused in the future. Pioneers like Madaster frame buildings as material banks, providing owners with an inventory that includes reuse potential and circularity indicators. Triodos Bank’s headquarters demonstrated this approach at scale by publishing a detailed passport to support future dismantling and high-value recovery.

Europe is formalizing traceability with the Digital Product Passport. Under the Ecodesign Regulation for Sustainable Products and the revised Construction Products Regulation, DPPs will store performance, safety, and environmental data in a machine-readable format and link this data to each physical product. The European Commission has launched its 2025 consultations on implementation, and the sector guide confirms that construction will be among the first sectors to phase in implementation over the next decade.

To ensure passports are easily accessible and reliable, GS1 identifiers and 2D barcodes are being adopted, enabling QR scanning to reliably access verified data for any user. GS1’s guide demonstrates how globally unique product identifiers and digital links support interoperability between databases and on-site scanning. This is crucial for reusing or safely removing products years after installation.

Secondary and recycled materials in construction

Steel is already a circular labor resource. Global analyses show that hundreds of millions of tons of recycled steel are consumed each year, preventing a significant amount of carbon emissions compared to new steel production. Technical protocols ensure that engineers can safely source recovered structural components through inspection and testing procedures published by the Steel Institute and the Structural Engineers Institute.

Concrete may contain recycled aggregates obtained from construction and demolition waste within a specific standard framework. EN 12620 specifies the properties of aggregates, including recycled sources, while the European Commission’s Joint Research Center documents the opportunities and obstacles for the widespread use of recycled aggregate concrete in member countries. These references are being turned into specifications that the design team can actually obtain by bringing together pilot projects.

Beyond the basic structure, manufacturers are launching products with very high recycled content that meet performance demands. For example, recently developed cable prototypes use 100% recycled copper and polymers, supported by specialized take-back and processing services. This demonstrates how supply chains can close the loop at the product level.

Smart materials and sensor/monitoring systems

Smart materials extend their service life by actively managing energy or repairing damage. Electrochromic glass reduces heat gain and glare by changing its tint in response to control signals while preserving the view. Field trials and national laboratory studies have demonstrated significant energy and peak load savings, as well as comfort benefits, when integrated with lighting and HVAC control. Such products are now being monitored and tested within robust federal and research frameworks.

Phase change materials store and release heat at specific temperatures, balancing temperature fluctuations in light envelopes and service areas. Recent studies and experimental work conducted in hot climates confirm that when PCMs are strategically placed within assemblies, indoor temperature fluctuations and cooling requirements are reduced. As regulations and supply advance toward full life-cycle performance, these latent storage strategies offer passive resilience without increasing operational complexity.

Sensors make the cyclical promise measurable. Internet of Things-based structural health monitoring networks now provide real-time data on stress, vibration, and crack propagation, enabling targeted maintenance and extending service life without invasive intervention. Recent studies indicate rapid progress in the fields of low-power sensing and data-driven diagnostics, positioning digital twins as a natural environment for integrating sensor streams with operations.

Digital tools: BIM, life cycle assessment, circularity metrics

Information management standards form the foundation. While the ISO 19650 series defines how project teams manage information throughout the asset lifecycle, openBIM standards such as IFC, now published as ISO 16739-1:2024, ensure that data is interchangeable between platforms and remains accessible for decades. buildingSMART’s current versions and tasks highlight how IFC is used by public clients and regulators for presentations and code checks.

Life cycle assessment has become mainstream policy and practice. The professional standard established by RICS for life cycle carbon came into effect for members on July 1, 2024, aligning asset decisions with a consistent methodology. Tools integrated with BIM models make this method functional: One Click LCA matches EN 15978 life cycle stages A1 to C4 with module D, while TallyLCA works within Revit to measure concrete impacts directly from model quantities.

Product-level evidence is harmonized through Environmental Product Declarations (EPDs) compliant with the EN 15804 standard. The A2 amendment, mandatory for new EPDs, tightens impact categories and reporting and clarifies benefits beyond system boundaries, thereby increasing comparability in procurement and enabling better circular accounting. The EC3 database then aggregates thousands of verified EPDs, allowing teams to compare and identify lower-carbon products during procurement.

The concept of circularity is advancing under international governance. The ISO 59000 series, which includes the ISO 59020 standard for measuring and evaluating circularity performance, provides organizations with a consistent indicator framework that complements carbon measurements. Designers can determine the circularity scores of products using the Ellen MacArthur Foundation’s Material Circularity Indicator, which is widely referenced in industry guidelines and research.

Business Models, Policy, and Incentives

Circular buildings mature when their design purpose is supported by reliable business models and clear rules. The shift is moving from selling products once to delivering performance over time, from the lowest capital cost supply to outcomes that preserve value throughout the entire life of the asset. Public policy is also moving in the same direction, making life cycle thinking and circularity visible in permits, tenders, and financing.

“Product as a service” / leasing of building components

Product-as-a-service means paying for the results delivered, not for the hardware. The well-known lighting example at Amsterdam Schiphol uses a pay-per-lux contract with Signify. The supplier retains ownership, provides maintenance and upgrade services, and takes back the lighting fixtures at the end of the contract period. The customer purchases a guaranteed light level and predictable service costs, while the manufacturer finds a reason to design modular, repairable products that can be recovered and remanufactured.

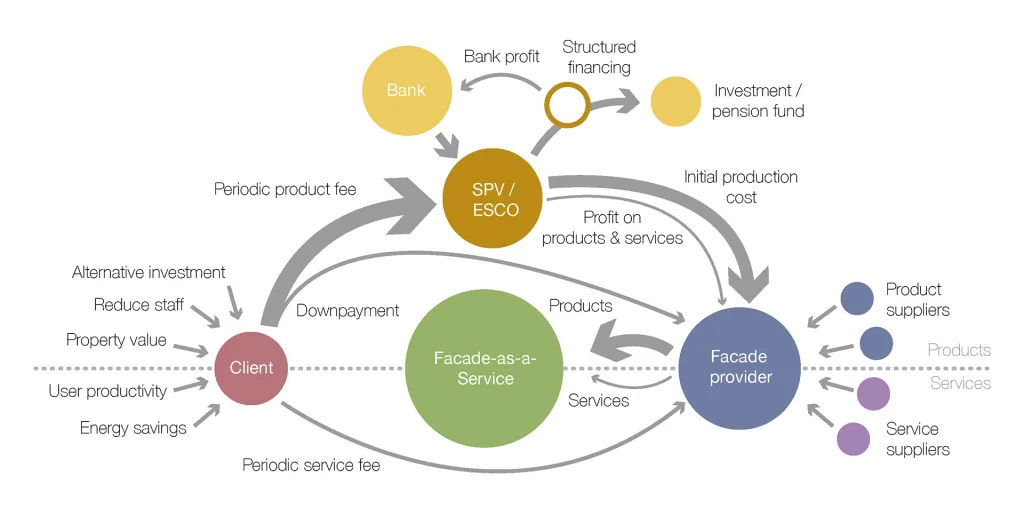

The service-based approach for larger building systems is also progressing. Facade-as-a-Service pilot projects conducted by TU Delft and Coalition Circular Accounting are testing performance-based leasing where the facade belongs to the supplier and is paid for as an energy, comfort, and maintenance service. These studies map the managerial and financial impacts, from measurement and performance verification to asset ownership in balance sheets and residual value at the end of the contract.

The same logic also underpins the “material-as-a-service” contracts initiated by RAU and Turntoo. In these contracts, suppliers retain ownership rights to the components, and material passports subsequently support recovery. When ownership remains with the manufacturer, durability and recyclability become business priorities rather than additional features.

Green procurement, incentives, and regulatory tools

Public procurement is a powerful accelerator. The European Commission’s Green Public Procurement criteria for buildings and the Level(s) framework provide a common language for contracting authorities to demand life-cycle performance, design for disassembly, and high-value reuse. Best practice guides show how to incorporate LCA and life-cycle costs into tenders, so that circular outcomes are evaluated alongside price and schedule.

Member states are turning these principles into regulations. The Netherlands requires the calculation of the Environmental Performance of Buildings (MPG) during the permitting phase and is tightening threshold values over time to encourage the selection of materials with lower environmental impact. France’s RE2020 regulation makes the entire life cycle performance, including carbon from construction materials, a matter of code. In the Nordic countries, Sweden requires climate declarations for new buildings, while Denmark has introduced concrete carbon limits for large projects and is signaling further tightening.

Cities are adding practical reuse incentives. Portland, Oregon, maximizes recovery by mandating the dismantling rather than demolition of old homes, while Vancouver ties demolition permits to minimum recovery and high reuse-recycling rates. These local rules create markets for recovered components and normalize circular practices on construction sites.

Extended producer responsibility is another lever. France launched an EPR program for construction products and materials in 2023, requiring producers to finance take-back networks, improve traceability, and support reuse and recycling. This shifts end-of-life costs upward and strengthens the business model for durable, recoverable products.

Contracts, leases, and guarantees in circular projects

Contracts must specify outcomes, ownership, and recourse. For service models, performance-based contracts define the metrics to be paid, the measurement method, service levels, and what happens if targets are not met. In lighting as a service, this may include lighting bands, uptime, response times, and data access for verification.

Reuse presents different risks than new purchases, so contracts and specifications must address issues of origin, testing, and liability. The Structural Engineers Institute’s guide specifies how to evaluate reclaimed components, document due diligence, and address legal and insurance issues in structural reuse. Practical contractor guides and toolkits from European reuse programs add procedures for quality rating, warranties, and roles at demolition sites.

Warranties are a known obstacle. While new products typically come with a supplier warranty, refurbished products are generally not covered by warranty. The UK industry guide highlights this gap and recommends strategies such as performance testing, third-party certification, and clearly stating residual risks in the contract to make reuse acceptable to customers and insurers.

Financing models and cost-benefit frameworks

Circular decisions require financial language. Life cycle cost is the standard method used to compare options that differ in terms of purchase price, service life, maintenance, and end-of-life value. ISO 15686-5 specifies the requirements for LCC, while the RICS guide implements this method for construction procurement and design. Using LCC early on helps teams evaluate the design for adaptability, dismantling, and take-back agreements rather than chasing the lowest initial cost.

Sustainable finance frameworks align capital with circular real estate. The EU Taxonomy defines criteria for environmentally sustainable activities, and these criteria are reflected in green bond standards for buildings. When issuers meet these criteria, especially if the entire life cycle and circular metrics are consistently disclosed, they can signal lower transition risk and better access to green capital.

Transition risk tools are as important as cost for investors and owners. CRREM pathways are widely used to check whether a portfolio is aligned with science-based decarbonization trajectories and to develop renewal plans. While CRREM currently focuses on operational energy, combining these pathways with concrete carbon and LCC analysis provides a more comprehensive picture of total costs and carbon over time. New guidelines are also emerging from development banks and industry organizations to align on what constitutes circular finance. These guidelines will help scale consistent investment decisions.

Case Studies and Lessons Learned

Evidence from completed projects demonstrates that circular strategies are not niche ideas, but rather practical approaches that transform how value is created and preserved in buildings. Comparative analyses of dozens of European cases also show that when teams plan for circularity from the outset, life cycle assessments can quantitatively measure the actual carbon and resource benefits.

Exemplary projects applying circular principles

Triodos Bank Office, Driebergen-Rijsenburg

RAU Architects delivered a wooden office designed as a material bank. The structure can be dismantled and reused because it is assembled with screws instead of adhesives. The material passport hosted on Madaster documents what is mounted where. The wooden structure is estimated to store 1,633 tons of CO2 and the building has received a BREEAM Outstanding certification, demonstrating both environmental and documentation performance.

Circl Pavilion, Amsterdam

ABN AMRO’s living laboratory is designed for easy disassembly and a high proportion of recycled and recyclable products. Recycled denim has been used for acoustic panels in the equipment, and integrated circular business models have been implemented to test performance-based supply and take-back processes. Circl has become a template for scaling circular contracts and material tracking within the bank.

Circle House, Aarhus

is a 60-unit social housing project that standardizes reversible connection elements and repeatable components, enabling up to 90% of the materials to be dismantled and reused at high value. The project’s open documentation serves as a teaching and replication tool for other clients and municipalities.

Temporary Courthouse, Amsterdam

Cepezed delivered a fully demountable courthouse that meets strict security and acoustic requirements. After serving for five years, this structure was dismantled and transported to Enschede, where it was reassembled as a research and office facility. This project demonstrates that reversibility can meet corporate standards while also preserving future value.

Resource Rows, Copenhagen

Lendager Group transformed bricks and timber sourced from large demolition sites into new facade and interior systems, supported by post-completion LCA and cost analyses. This example demonstrates how industrial transformation can meet architectural quality while simultaneously reducing concrete impacts.

Success criteria: environmental, economic, social

Environmental projects report on full life cycle metrics rather than anecdotes. Triodos’s timber-framed warehouses are biogenic carbon sinks, and their demountable design enables components to be reused rather than recycled, reducing future end-of-life impacts. Circle House establishes a verifiable reference point that other teams can adopt by publishing a quantitative reuse target at the component level. Resource Rows has been evaluated with a post-completion LCA and has shown that industrial recycling can reduce upfront impacts compared to similar designs using conventional products.

The owners of Circl documented how service models, buyback, and residual value considerations changed the business model. Circular construction reports transform the lessons learned from the pavilion into repeatable business models for suppliers and customers, while also including BIM-linked material passports to support asset management and valuation. Demountable projects such as the Temporary Courthouse eliminate the risk of change of use by treating components as recoverable inventory rather than sunk costs.

Social

Circl operates as a public learning space and meeting venue that promotes circular practices in supply chains. Paris 2024 brought circular ideas to the city level by using approximately 95% of existing or temporary venues and demonstrated how policy and procurement can increase social access and transparency by committing to reuse or repurpose temporary equipment.

Challenges, pitfalls, and trade-offs encountered

Quality assurance and responsibility

Specifying recycled components, particularly structural steel or facade elements, adds testing and documentation tasks that must be planned early. Recent guidelines from professional bodies detail inspection, certification, and design protocols for the reuse of structural steel, clarifying what is acceptable and how to demonstrate this to insurance companies and authorities.

Supply chain readiness

Many cases show that the large-scale supply of consistent recycled products is still inconsistent. The Circl team solved this problem by making take-back agreements, developing a material database, and treating the pavilion as a live supply experiment. If agreements are not made early on, teams risk reverting to traditional sourcing methods in later stages of the program.

Cost and schedule trade-offs

Circular assemblies, especially when using reversible fasteners or non-standard products, can extend coordination time. Resource Rows demonstrate that these costs can be offset if the design standardizes recycled systems and integrates LCA and life-cycle cost analyses into the decision-making process rather than adding them at the final stage.

Scalability and repeatability across contexts

Standardize the rules, then standardize the parts

Circle House demonstrates that simple, repeatable interfaces and validated connections enable very different housing types to share the same reversible kit. Publishing clear technical guidelines and targets, such as a 90% high-value reuse goal, helps other teams adopt this approach without copying the architecture.

Demonstrate movements at the building scale, then scale up through policy

The Temporary Courthouse, when the recyclable detailing was included in the original draft, demonstrates that buildings can be completely dismantled and relocated. City and event platforms are also promoting these ideas. Paris 2024’s heavy reliance on existing and temporary venues, combined with a commitment to reuse temporary equipment, creates a public reference point for future host cities and major programs.

Clearly state the business model

ABN AMRO’s Circl study links circular design choices to banking models, from performance-based payment services to material passports that support value recovery. The working guides show owners how to incorporate circular performance into contracts and governance, so that lessons learned become standard practice across the portfolio.