Definition of the concepts of carbon negative, net zero, and carbon neutral

The meaning of each term.

Net zero CO₂ means achieving a balance between CO₂ emitted and CO₂ removed, resulting in a net zero contribution to the atmosphere. Globally, the IPCC treats the concepts of “net zero CO₂” and “carbon neutrality” as equivalent. Carbon negative, sometimes also called net negative, means that the amount removed exceeds the amount emitted, resulting in less CO₂ in the atmosphere than before.

LWK + PARTNERS

How are they used in the construction sector?

In buildings, we calculate the carbon that arises throughout the entire life cycle: carbon from material production and the construction of the project (internal carbon, including “pre-carbon”), energy used to operate the building, and the end-of-life stage. Carbon neutral or net zero projects balance these totals. Carbon negative projects go further by storing carbon in materials and removing extra carbon beyond their emissions. WorldGBC emphasizes that pre-emissions from materials will account for approximately half of new buildings’ carbon emissions between now and 2050, so definitions must include tangible carbon, not just energy.

A simple rule.

Net-zero or carbon-neutral buildings achieve balance. Carbon-negative buildings leave the atmosphere in a better state than they found it. The IEA summarizes it as follows: Being carbon-negative requires removing more CO₂ than is emitted.

A concrete example of this.

The Powerhouse Brattørkaia in Trondheim is energy positive throughout its lifetime, exporting more renewable electricity than it consumes. Energy positivity is a powerful concept, but it does not automatically equate to carbon negativity unless the emissions generated over its lifetime are less than the emissions offset and stored.

The historical development of low-carbon architecture

From efficiency to performance standards.

After the oil crises of the 1970s, the first green buildings focused on energy conservation. In 1990, the United Kingdom launched BREEAM, the first national sustainability rating system. In 1991, the Passive House approach codified ultra-low energy demand. In 1998, the USGBC piloted LEED, spreading broader sustainability criteria.

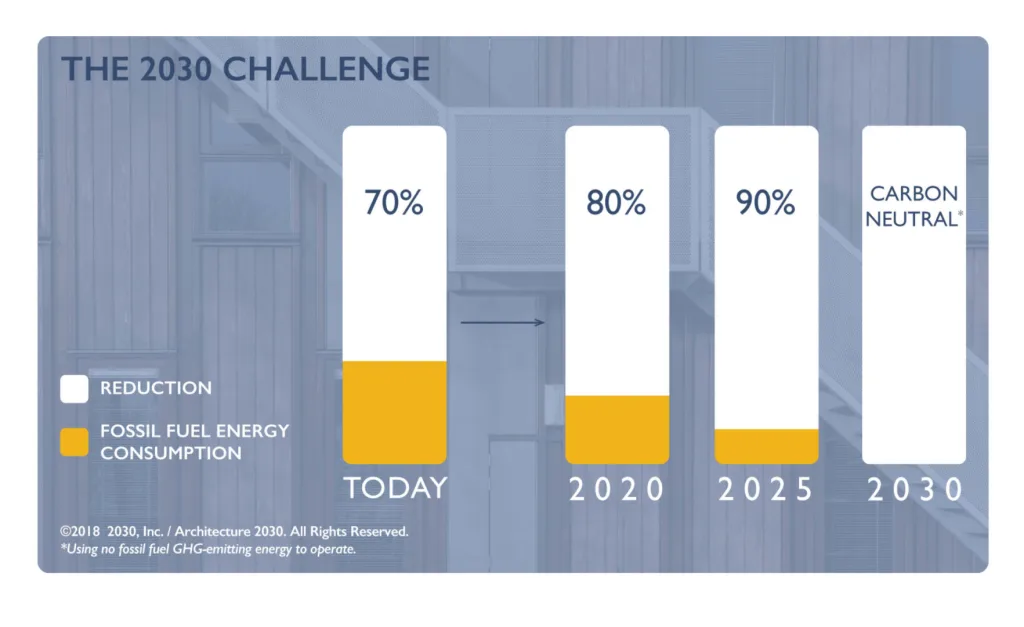

From labels to climate goals.

In 2006, Architecture 2030 launched the 2030 Challenge to steer the profession toward zero-carbon buildings. In 2019, the WorldGBC’s “Bringing Embodied Carbon Upfront” program focused the sector on whole-life cycle carbon, and RIBA’s 2030 Climate Challenge set phased targets for operational and embodied carbon performance.

From energy to materials and storage.

The discussion expanded from operational energy to carbon-storing materials. A study published in Nature Sustainability showed that large-scale use of engineered wood could transform part of the building stock into a long-term carbon sink by storing biogenic carbon and preventing emissions from cement and steel. High-profile projects like the Sara Kulturhus wooden building in Sweden claim to achieve a carbon-negative balance for approximately 50 years thanks to stored carbon and green energy systems.

BWhy is this change important right now?

Despite increases in efficiency, the floor area and emissions of buildings continue to rise. International assessments warn that building emissions have increased since 2015 and that more comprehensive measures are needed across the entire value chain, including materials. Renovating existing buildings is also critical, as most of the building stock in 2050 already exists today.

The importance of carbon negativity in 21st-century design

The scale of the impact.

Depending on the method and year, buildings account for approximately one-third to two-fifths of global energy-related CO₂ emissions. WorldGBC and Architecture 2030 state that when you include operations and materials, the built environment accounts for approximately 39 to 42 percent. According to UNEP’s latest report, buildings account for approximately one-third of global energy use and emissions. This scale means that design choices play a significant role in the global carbon balance.

Climate math. Not only stopping warming, but also reducing it after excessive warming, the IPCC’s scenarios show periods of net negative CO₂ globally, along with rapid cuts. In buildings, this means reducing operational emissions to near-zero levels and addressing the large preload from materials.

How carbon-negative design is applied in practice.

- Store carbon in the structure. Mass timber frames and bio-based coatings can sequester biogenic carbon for decades. At the city scale, if forests are managed responsibly and substitution effects reduce the use of cement and steel, this strategy can create a resilient carbon sink.

- Choose carbon-storing materials. LCAs show that hemp-lime mixtures and straw-based structures can be nearly zero-carbon or even carbon-negative from production to consumption due to plant growth and carbonation. New research on biochar-enhanced concrete shows additional carbon sequestration potential while maintaining strength.

- Eliminate operational emissions and export clean energy. Electrify building systems, operate them with on-site renewable energy sources, and design them to generate surplus. Energy-positive examples like Powerhouse Brattørkaia demonstrate that roofs and facades can collect enough solar energy to supply neighbors and public transport. By combining this with carbon-storing materials, a project can go beyond net zero to become net negative.

- First, design for reuse and renovation. The lowest-carbon building is usually the one you don’t demolish. Global analyses and reports emphasize renovation and circularity to prevent pre-emissions from increasing repeatedly.

Real-world signals.

Sara Kulturhus in Sweden ranks among the tallest wooden buildings and is reported to be carbon negative over a 50-year period thanks to the carbon stored in the wood and its renewable energy system. While the claims need to be verified with transparent life cycle assessments (LCAs), the path forward is clear: combine bio-based storage with zero-carbon operations and careful end-of-life strategies.

Basic Principles and Strategies

Concrete carbon minimization (materials, supply, construction)

Measure first, then design according to the carbon budget.

Conduct carbon assessment throughout the entire life cycle, starting from the concept phase, and monitor it throughout the design process. Use the EN 15978 life cycle modules to make choices visible: A1–A3 for the product phase, A4–A5 for transport and site, B for use, C for end-of-life, and D for beyond system boundaries. Setting a project carbon budget and updating it as designs change ensures everyone is honest. RICS’s 2023 WLCA standard explains the modules and how they should be reported consistently.

Select low-carbon products using EPDs and the EC3 database.

Specify materials with verified Environmental Product Declarations (EPDs) compliant with the EN 15804+A2 standard. Tools like Building Transparency’s EC3 enable teams to compare EPDs by product and supplier, allowing you to purchase the lowest-carbon mixes in your region rather than the industry average. Make EPD presentations and maximum kgCO₂e limits part of the purchasing process.

Reduce carbon emissions from concrete and steel, the two largest contributors.

For concrete, reduce clinker and cement usage where appropriate by using alternatives such as limestone-calcined clay cement (LC3) or high slag blends, and evaluate CO₂ mineralization technologies that inject CO₂ into fresh concrete and permanently bind it. Significant trials and studies show that LC3 can reduce cement-related emissions by approximately 30 to 40 percent. CarbonCure’s case study at Amazon HQ2 demonstrates large-scale application in the short term. For steel, prefer recycled content from electric arc furnaces and reuse salvaged parts whenever possible.

Design to use fewer materials and more reused components.

Use openings of the correct size, employ efficiency-focused structural systems, and avoid excessive specifications. Plan for disassembly using bolted connections instead of welded joints, and retain material passports for future reuse. Examples from London’s circular projects show that structural steel recovered from one site and reused at another reduces both cost and carbon emissions. Organizations such as Rotor Deconstruction demonstrate how recovery and resale ecosystems make this practical.

Clean up the construction site.

Aim for A4–A5 reductions through off-site prefabrication and zero-emission machinery to consolidate logistics and reduce waste. Oslo’s policy now mandates the use of emission-free equipment in public projects, and electric facilities are already operating on actual sites. C40’s Clean Construction program offers city and customer targets for zero-emission construction sites and significant carbon emission reductions by 2030.

Remember the general situation between embodied carbon and operational carbon.

As networks decarbonize, pre-emissions account for a larger portion of the total impact. The WorldGBC’s “Bringing Embodied Carbon Upfront” report states that embodied emissions could exceed half of the total for new construction between 2020 and 2050. Therefore, early material choices are important.

On-site carbon sequestration and biogenic strategies

Store carbon in the building, then report it transparently.

Log wood, straw, hemp lime, and other bio-based building elements can store biogenic carbon for decades. Since the carbon removals in A1–A3 are balanced by emissions in C modules depending on the scenarios, report storage and end-of-life processes transparently. Use existing guidelines to avoid perverse incentives and compare similar wood EPDs.

Green roofs, living landscapes, and urban trees are small but real carbon sinks.

Green roof studies estimate above-ground biomass storage at 0.16 kg C per square meter for extensive sedum systems. This potential is even higher on deeper or more biodiverse roofs. Urban forestry multiplies benefits such as shade, cooling, air quality, stormwater control, and long-term carbon storage. Design with species and shade goals, then quantify and maintain reliability using i-Tree or city-scale studies.

Improving soil carbon with biochar.

Improve in-situ soils, pots, and rain gardens with certified biochar to increase carbon retention time, enhance water retention capacity, and support vegetation. Research shows that urban blue-green spaces improved with biochar from crop residues can store significant amounts of carbon per hectare while improving stormwater performance. Refer to local standards for safe use.

Use pilot biological carbon capture envelopes in suitable locations.

Algae photobioreactor facades like BIQ in Hamburg show a different approach: grow biomass on glass panels that shade the building and generate energy input. These systems are still in their infancy and context-dependent, but they demonstrate how envelopes can become active carbon cycle infrastructure.

Renewable energy integration and surplus energy design

First reduce demand, then electrify, then produce and share.

Start with high-performance insulation and airtightness targets that meet or exceed Passive House criteria, because every kilowatt-hour not needed is the cheapest and cleanest energy. Electrify heating and hot water with heat pumps to align loads with the decarbonized grid. Only then scale up on-site renewable energy sources and storage to meet remaining needs and capture surplus.

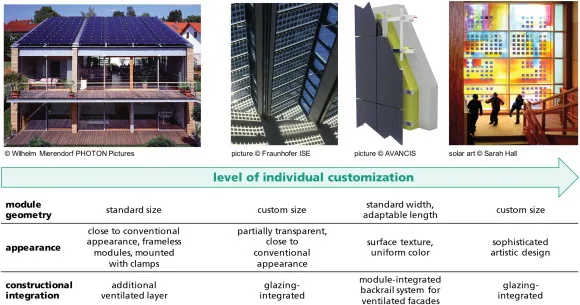

Design PV as an architectural element, not as an afterthought.

Use building-integrated photovoltaic systems to cover roofs and facades or convert roof coverings into generators. While Fraunhofer ISE and IEA PVPS provide design guidelines for BIPV, NREL’s PVWatts system offers early yield estimates that provide information on mass, slope, and orientation. Treat PV like other facade systems, considering drainage, fire, and maintenance details.

https://www.sciencedirect.com/science/article/pii/S0378778819339155

Turn buildings into flexible grid citizens.

Pair PV with batteries and controls so that building loads can be shifted and reduced, charged when renewable energy sources are abundant, and exported when the grid needs it. DOE and NREL define grid-interactive efficient buildings and microgrids that increase resilience and generate revenue from flexibility. This turns excess energy from being just a nice idea into a project asset.

Aim for a proven, verified surplus, as demonstrated by previous examples.

Energy-positive showcases like Powerhouse Brattørkaia and Powerhouse Telemark demonstrate that with careful design, deep efficiency, electrification, and large PV arrays, buildings can eventually produce more energy than they consume and sometimes even supply energy to neighbors and electric mobility via local microgrids. Use these as proof points, then replicate the same approach while considering local climate and policy.

Reality checks to ensure designs are realistic.

Grid carbon factors change over time, sunlight is scarce in winter, and shading from neighboring buildings is important. Use conservative assumptions, model seasonal storage only where applicable, and publish measured performance post-use. When surplus is real, residual emissions from A modules can be balanced and make a project net negative over its lifetime. WorldGBC’s call to reduce pre-emissions now makes this synergy between low carbon emissions and clean operations indispensable.

Material Innovations and Sustainable Systems

Biologically based and carbon-capturing materials (e.g., hempcrete, mycelium)

How they store carbon and what the numbers mean.

Plants draw carbon from the air as they grow; if we lock this biomass into long-lasting structural elements, we can store that carbon for decades. Hemp-lime mixtures add another feature: the lime binder slowly reabsorbs CO₂ through carbonation after placement. Multiple life cycle assessments report very low or even negative cradle-to-gate carbon footprints for hemp-based assemblies when biogenic storage is carefully accounted for and end-of-life scenarios are transparent.

Mycelium composites on walls and in interior spaces.

Mycelium grown on agricultural byproducts creates lightweight, insulating panels and blocks. Recent LCAs have found significantly lower climate impacts compared to traditional masonry and mineral insulation; however, there are some trade-offs depending on the substrate source and production energy. Early applications stand out in acoustic panels, interior partitions, packaging substitutes, and non-load-bearing facade cassettes, where low density and circularity are most important.

Properly identify bio-based systems.

Treat moisture as a top-tier design issue: ventilated rain screens, capillary-active plasters, and careful detailing around openings keep bio-based layers dry. Ensure consistent biogenic carbon accounting across all products by requesting EN 15804-compliant EPDs, and combine bio-based coatings with reversible fasteners for future reuse instead of sending them to landfill.

Advanced concrete alternatives and low-carbon cement substitutes

Start with the low-clinker cements used today.

Portland-limestone cement (Type IL/PLC) typically mixes 5-15% limestone into the clinker, and when mix designs are validated, it can reduce CO₂ in the cement by approximately 8-10%. At the concrete level, this usually means a double-digit reduction in GWP from cradle to gate without changing construction methods.

Scale deeper substitutions with LC3.

Limestone-calcined clay cement (LC3) replaces approximately half of the clinker with calcined clay and limestone, enabling a reduction of approximately 30-40% in emissions using abundant materials and existing plant equipment. As LC3 standardization and supply chains expand, this is a practical way to achieve significant reductions in the short term.

Use CO₂ mineralization and CO₂-cured concrete whenever possible.

Injecting captured CO₂ into fresh concrete mineralizes it into stable calcium carbonate, thereby reducing the amount of cement required for the same strength and permanently binding a small amount of CO₂ within the matrix. At the project scale, Amazon’s HQ2 project specified CarbonCure mixes and reported saving approximately 1,000 tons of CO₂ over 100,000 cubic yards, demonstrating the feasibility of large-scale use in the short term. Systematic investigations of mineralization pathways confirm a significant carbon reduction potential in various concrete products.

Evaluate alkali-activated and geopolymer concretes for niche applications.

When alkali-activated binders, precursors, and activators are responsibly sourced, they can significantly reduce global warming potential compared to ordinary Portland cement; however, LCAs highlight some disadvantages in other impact categories and supply variability. They may be attractive options for precast elements and industrial floors where curing and quality control are stringent.

Follow evolving standards that enable higher substitution rates.

European cement standards now include families such as CEM II/C-M and CEM VI, enabling multi-component mixtures with much lower clinker ratios compared to older cements. Designers can write performance-based properties that allow these new binders and avoid defaulting to high clinker types.

Carbon capture systems, living walls, and soil systems

Industrial carbon capture transforming the cement we buy.

In June 2025, Heidelberg Materials commissioned Brevik CCS in Norway. This is the first full-scale carbon capture system installed at a cement plant, with the capacity to capture approximately 400,000 tons of CO₂ per year and supply net-zero “evoZero” cement. The company and governments are now scaling up this model to plants such as Padeswood in Wales, signaling that carbon-captured cement, though expensive, will be a real market option within this decade.

Building-integrated capture systems are emerging but are not yet widespread.

Researchers are testing DAC modules attached to rooftop units or integrated into commercial HVAC systems to remove CO₂ from large indoor air streams, sometimes improving indoor air quality and reducing the need for outdoor air. Early modeling and laboratory pilots are promising, but energy and cost constraints persist, and independent reviews caution against over-reliance until real-world performance is proven. If you investigate this, evaluate it as R&D with transparent measurement.

Living walls for air, heat, and microclimate.

Plant-covered facades and canyon-scale greenery can reduce roadside pollutants by increasing accumulation on leaf surfaces. Street canyon modeling studies show significant reductions in NO₂ and particulate matter. Studies also document that when systems are properly designed and watered, heat flow through facades decreases and cooling needs are reduced. Since pumps, substrates, and replacement cycles create tangible effects, always match the benefits to life cycle controls.

Algae facades as active envelope pilots.

The BIQ house in Hamburg features a photobioreactor facade that cultivates microalgae, shades the apartments, and meets part of the thermal demand, offering a rare real-world test environment for carbon cycle facades. Although still a niche solution due to maintenance and cost challenges, this example demonstrates how facades can be transformed from passive coatings into mini bio-factories.

Soil systems that store carbon and biochar in water management.

At ground level, urban trees and healthy soils are resilient carbon sinks; city-scale studies estimate that tree canopies store an average of 7.7 kg of carbon per square meter and that annual carbon sequestration increases as canopies grow. Improving pots, rain gardens, and roadside soils with certified biochar adds long-lived carbon to the soil matrix while improving leaching and contaminant removal, which supports vegetation cover during heat and drought. Design these layers, like other systems, with characteristics such as raw material, particle size, dosage, and leaching control.

How can I add this to the project summary?

Request full life-cycle carbon targets that combine bio-based storage, low clinker binders, and measured operational energy. Where the market allows, conduct pilot applications of mineralized concrete or carbon-captured cement and track the results. Evaluate living walls and soils as climate infrastructure with maintenance budgets, moisture and health sensors, and simple reporting, so that gains are reliable.

Design, Planning, and Modeling Tools

Life cycle assessment (LCA) and carbon accounting models

What is LCA and how is it structured?

Use LCA to calculate the impacts of a building throughout its entire life cycle. At the building scale, EN 15978 results are divided into modules: A1 to A3 product phase, A4 to A5 construction, B use phase, C end-of-life, and D cross-border reuse and recovery. At the methodological level, ISO 14040 and 14044 define the principles for objectives and scope, inventory, impact assessment, and interpretation, while EN 15804 sets the rules for how product EPDs are created and reported. These three references form the basis for reliable carbon accounting.

Tools that make counting practical. Commonly used packages include all building calculators such as Tally with Revit or the free TallyCAT for in-model assemblies, EC3 for comparing supplier-specific EPDs and setting maximum kgCO₂e targets, and Athena Impact Estimator for testing mass and assemblies early on. RICS’s 2023 WLCA standard brings these together with consistent reporting and scopes.

A simple workflow that teams actually use.

- Establish a carbon budget in the concept design and align it with EN 15978 modules. 2) In schematic design, conduct rapid whole-building LCA studies and flag problematic areas. 3) During design development and procurement, request EN 15804+A2 EPDs and use EC3 to select lower-carbon mixes based on the facility and supplier. 4) Publish the WLCA at delivery and review it after one year of operation. This sequence reduces emissions both upfront and during use while keeping documentation ready for audit.

Parametric and generative design for carbon optimization

Why parametric models are helpful.

Carbon results are sensitive to geometry, structure, envelope, and systems. Parametric models allow you to systematically vary these inputs and then evaluate thousands of options. Multi-objective optimization tools like NSGA-II or Grasshopper tool sets such as Wallacei, Octopus, and Galapagos help you search for Pareto-optimal designs that balance daylight, energy, and embodied carbon, rather than pursuing a single metric. Research and open-source applications demonstrate that NSGA-II finds balanced solutions between comfort, solar access, and loads.

What needs to be optimized and how should the engines be connected?

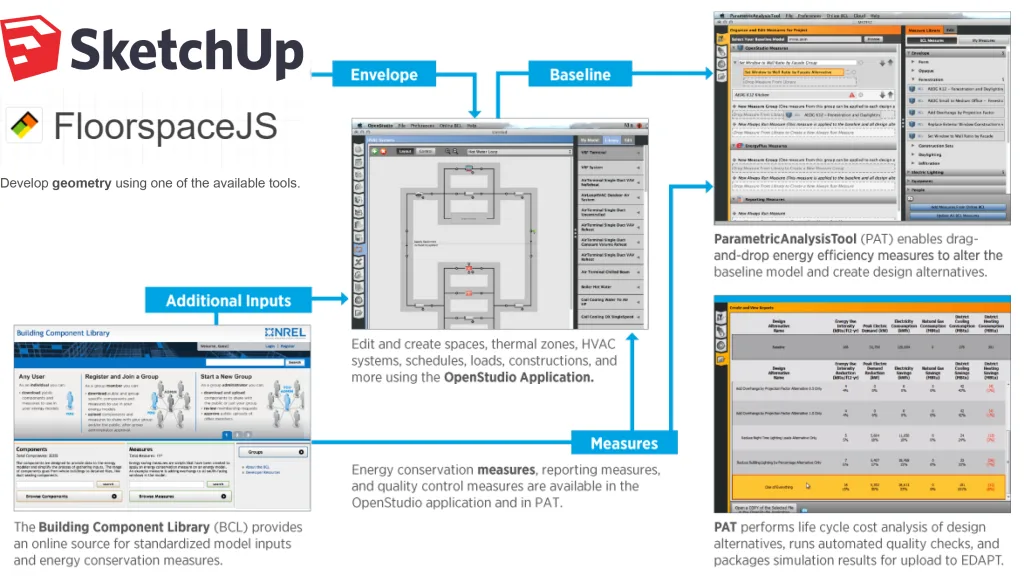

Connect your geometry to the energy and daylight engines, then add a concrete carbon cycle. A commonly used stack includes Ladybug Tools for climate analysis, Honeybee for Rhino-Grasshopper, Radiance, and EnergyPlus runs, Karamba3D for material-efficient structures, and EC3 or Revit add-ins for live concrete carbon comparisons. This links form, structure, and materials to actual performance rather than general rules.

From the option selection phase to the shortlist.

Automate the design space exploration and interpret the results through the Pareto lens. NREL’s OpenStudio Analysis Framework can coordinate scaled parametric EnergyPlus studies, while Autodesk Insight adds early carbon readings to the Revit workflow.

Climate-responsive design and simulation tools

Model climate, sun, wind, and light with validated engines.

Combine Ladybug Tools for climate diagrams and outdoor comfort from room scale to regional scale, Honeybee for Radiance daylight and EnergyPlus energy models, and Dragonfly for regional energy with URBANopt. These are open-source interfaces built on validated engines that make climate-sensitive early design choices visible to designers.

Use specialized tools when the problem requires it.

For daylight quality and glare, ClimateStudio offers annual DGP workflows and LEED daylight credit simulations. For dynamic thermal modeling and UK overheating controls, it supports IES VE, TM52, and TM59 assessments. For neighborhood microclimate and heat reduction strategies, ENVI-met simulates vegetation, surfaces, wind, and radiation at high resolution to test shade trees, cool materials, and courtyard forms.

Case Studies and Sample Projects

Powerhouse Telemark – Norway’s carbon-negative office example

Key features.

Powerhouse Telemark is an 11-story office building located in Porsgrunn. The design team states that this building will generate more energy than it consumes over its lifetime and reduce annual energy consumption by approximately 70 percent compared to a typical new office. The building, which holds a BREEAM Excellent certification, is part of the Norwegian Powerhouse program, which aims for energy positivity throughout its life cycle.

Design elements you can draw inspiration from.

The 24-degree sloped roof and PV-covered south facade maximize solar energy gain and together are expected to produce approximately 256,000 kWh of energy per year. The building facade is super-insulated with triple glazing, and ground-coupled systems provide efficient heating and cooling via deep geothermal wells. Standardized interiors have been selected to reduce waste when tenants change the interior layout.

How does it approach carbon negativity?

The broader Powerhouse definition accounts for the energy used in materials, construction, operation, refurbishment, and end-of-life. By exporting more clean energy than it consumes, this approach can offset life-cycle emissions when grid displacement credits are granted and achieve a net negative carbon balance across the entire life cycle. See the consortium’s published definitions and the sister project Brattørkaia for how this calculation is performed.

Tecla House – 3D-printed carbon-capturing house

What is it?

TECLA is a full-scale prototype house printed from locally sourced raw earth by WASP and Mario Cucinella Architects. The team describes this house as a circular housing model made from recyclable, locally sourced materials and designed to be carbon neutral.

Performance and construction speed.

The double-domed shell was printed in approximately 200 hours and covers an area of approximately 60 m². This demonstrates that earth structures can be digitally produced at a building scale with minimal imported materials and low processing energy.

Why is it important for carbon-negative design?

Since walls store biogenic and mineral carbon from local soils and agricultural fibers, and transportation and production are minimized, TECLA demonstrates the path to ultra-low carbon emissions. At best, it can be seen as a template for climate-resilient, low-impact housing where local soils are suitable and regulations permit the soil structure.

Other new global projects promoting carbon negativity

Carbon-storing tall trees – Sara Kulturhus, Sweden.

White Arkitekter’s 20-story cultural center and hotel was designed with a documented carbon budget. The team reported that total emissions over 50 years amount to 5,631 tons of CO₂e, balanced by 10,190 tons of CO₂e from biogenic carbon stored in the timber and on-site PV displacement, achieving a net negative balance in their framework. Independent reports also highlight the same claim and link to the study.

City-scale energy exporters – Powerhouse Brattørkaia, Trondheim.

This office is the northernmost energy-positive building and is designed to produce more energy than it consumes over its lifetime, including the energy used in its construction and materials. On average, it produces more than twice the electricity it uses daily and supplies energy to its neighbors and electric transport via a microgrid.

Noteworthy urban examples – PAE Living Building and Atlassian Central.

The PAE Living Building in Portland aims to achieve full Living Building Challenge certification and is designed for net-zero carbon and net-positive energy using on-site and off-site solar energy with battery storage. In Sydney, Atlassian Central is a hybrid timber tower currently under development that aims to reduce its predefined carbon emissions by approximately 50% and operate entirely on renewable energy, demonstrating how large commercial projects can reduce both carbon emissions and energy consumption.

Challenges, Risks, and Trade-offs

Initial investment costs versus life cycle gains

The money puzzle.

High-performance insulation, electrification, photovoltaics, and better materials can increase initial costs. However, comprehensive studies show that lower electricity and maintenance bills typically recoup any premium within a reasonable timeframe, and in many markets, rental and value premiums are now seen for certified assets. JLL reports rental increases of approximately 7 to 12 percent for green-certified offices, which strengthens the business model beyond energy bills. However, performance differences emerge when delivery or operations fall short, meaning savings are not automatic.

Who pays, who benefits?

Financing may be hindered by conflicts of interest between landlords and tenants. In this case, landlords cover renovation costs, but tenants benefit from the savings on their bills. The IEA’s latest guide still identifies this as the biggest obstacle, and the US Department of Energy’s Better Buildings resources recommend green leasing clauses to balance costs and benefits. These tools help reveal life-cycle value by transparently sharing savings.

Time, permits, and grid queues add soft costs.

Even if the project economics work on paper, interconnection and permit delays for on-site solar create program risk and additional soft costs that can reduce payback. NREL’s 2024 updates and program pages document queue backlogs and the need to streamline permitting and interconnection processes. Add contingency plans for these frictions to ROI models.

Technical, regulatory, and stakeholder barriers

Codes are evolving, but not uniformly.

The 2021 International Building Code introduced new types of log wood allowing up to 18 stories, but their adoption varies by jurisdiction and introduces new inspection and fire protection requirements. Insurance companies and lending institutions are still refining their risk models for tall wood buildings and often cite moisture and water damage concerns during construction as significant insurance issues that can slow projects or lead to repricing.

People and skills.

Building large-scale low-carbon buildings requires trained designers, installers, commissioning agents, and facility operators. IEA employment analyses show that the construction sector faces a serious staffing shortage on the path to net zero, and many international organizations are calling for targeted training to address skill gaps in renovation and heat pumps, building envelopes, and control systems. Plan for training and quality assurance in the budget.

Energy and grid infrastructure.

Long connection queues, uncertain tariffs, and variability in permits can hinder surplus energy strategies and community-scale systems. NREL highlights these bottlenecks in its latest industry updates. DOE’s grid connection roadmap, however, reveals process fixes that will take time to deliver results. Early involvement of public utilities and phased designs help manage these risks.

Uncertainties regarding long-term carbon accounting and resilience

Counting carbon is not the same as reducing it.

All life cycle carbon results depend on data selection. The RICS 2024 WLCA standard requires scenario transparency for use and end-of-life stages, and UK product councils note that EPDs vary in data quality and comparability even under EN 15804+A2 rules. Key point: publish assumptions, use verified EPDs, and perform sensitivity tests to ensure decisions are not dependent on a single data set.

Biogenic storage relates to timing and end-of-life.

For wood, hemp, and other bio-based systems, calculation methods differ regarding how temporary storage and release should be valued. The Carbon Leadership Forum details the current inconsistencies between wood EPD rules. Recent reviews also indicate that dynamic LCA and GWPbio can yield different results depending on the time horizon and end-of-life scenarios. Designers should clearly report storage and release and avoid double counting.

Material durability and longevity.

Moisture is the primary technical risk for mass timber; industry guidelines and research emphasize the importance of strict protection and moisture management plans during construction to prevent decay and serviceability issues. For landscape sequestration, biochar can hold a large portion of carbon for decades to centuries, but longevity varies depending on the raw material and climate, making specifications and monitoring important. Mineralized CO₂ in concrete is considered quite stable as calcium carbonate, but the net climate benefit depends on verified cement reduction and measured uptake quantities. Treat all three as engineering systems through implementation and measurement, not as assumptions.

Future Trends and Opportunities

Scalable replication and policy incentives

Next-generation policies that reward carbon performance.

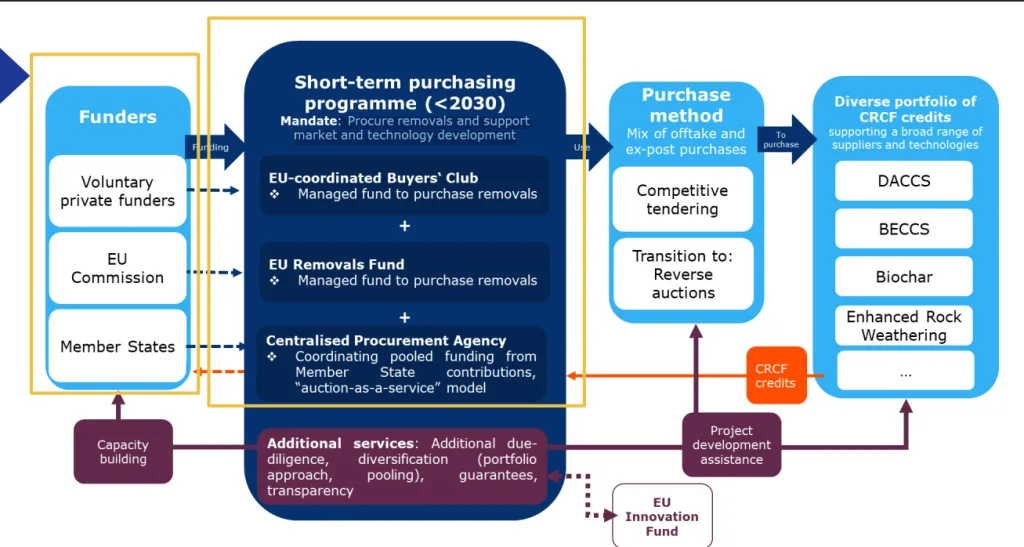

The EU’s recast Energy Performance of Buildings Directive of 2024 sets a clear timeline for zero-emission buildings: January 1, 2028, for public buildings and January 1, 2030, for all other new buildings. In parallel, the EU Carbon Removal and Carbon Farming Regulation (CRCF, 2024/3012) establishes the first EU-wide voluntary framework to certify removals, including long-term storage in products, which can also cover bio-based building components. These are built upon Level(s), the EU’s common lifecycle framework that extends the application beyond energy to materials and circularity. Together, these regulations form a policy package that rewards carbon leadership throughout the entire lifecycle, rather than just operational efficiency.

Public procurement for rapid scaling.

In the United States, the Inflation Reduction Act, the GSA’s Buy Clean pilot programs, and the EPA’s Low Carbon Materials program are financing the adoption of low-carbon materials at the federal level, encouraging suppliers’ EPDs and regional low-carbon mixes. Cities are also taking action: C40’s Clean Construction commitments aim to halve carbon emissions in major projects by 2030 and promote zero-emission construction sites, with progress tracked in annual reports. In the UK, the pilot version of the Net Zero Carbon Buildings Standard provides a single cross-sector benchmark for both operational and carbon emission performance that customers can currently reference.

How can project teams contribute?

Write specifications that reference these tools: Mandate EN 15804 EPDs, use Buy Clean-style maximum kgCO₂e thresholds in tenders, and align design targets with Level(s) and, where relevant, the UK Net Zero Carbon Buildings Standard. During the planning phase, follow London’s Circular Economy Declaration approach to finalize reuse and demolition outcomes during the approval phase.

Integration with circular economy and material reuse

From demolition to urban mining.

London’s Circular Economy Declarations already require applicants to demonstrate how waste from demolition will be reused or recycled and how the design will facilitate future dismantling operations. This presents a model that other cities can adopt in their guidance and planning conditions by modifying projects towards preservation, reuse of components, and modularity.

Data rails for large-scale reuse.

Material passports and the upcoming EU Digital Product Passports create the necessary metadata to track what is in a building and how it can be reused. Platforms like Madaster make passports functional for assets and portfolios, while the UKGBC and European Commission’s Level(s) program explains how data should be standardized throughout the life cycle. These tools transform materials from waste into managed assets with residual value.

City strategies that turn circularity into reality.

Since 2020, EU policy has placed construction at the heart of the Circular Economy Action Plan, and cities such as Amsterdam are supporting this by aiming to halve virgin material use by 2030 on the path to becoming fully circular cities by 2050. More planning systems are expected to require circular design reports, pre-demolition inventories, and evidence of reuse pathways.

Potential for carbon-negative urban planning and master plans

Urban carbon sinks through materials, soils, and trees.

If forestry is sustainable and the impacts of land use are manageable, master plans can physically store carbon by expanding log construction at the neighborhood scale. Peer-reviewed studies show that large-scale timber use can store CO₂ in the building stock and prevent emissions from cement and steel, but also emphasize the need for measures regarding land and biodiversity. Cities can add resilient soil carbon by converting green waste into biochar. Stockholm’s biochar program provides district heating and sequesters carbon in urban planting beds.

Regional-scale energy systems that export clean energy.

Carbon-negative urban planning is achievable by reducing operational emissions to near-zero levels and then producing excess clean energy. District heating networks that integrate heat pumps, wastewater or data center waste heat, and seasonal storage are a proven way to significantly reduce emissions and provide resilience. DOE’s URBANopt study and recent reviews summarize how these networks can be planned; when combined with district PV and storage, neighborhoods can eventually offset remaining concrete emissions.

Repeatable urban examples worth following.

Stockholm Wood City is a large-scale living test of wood urbanism, aiming to build thousands of homes and workplaces by leveraging the advantages of faster and lower-carbon construction. This type of integrated approach, combined with Scandinavian biochar programs and clean regional energy, points to urban areas approaching a net negative balance when the entire life cycle account and verified export are included. The biggest caveat is governance: masterplans must mandate LCA, responsible sourcing, and post-use measurements to maintain the credibility of carbon claims.