The human body is quite adept at hiding its internal noise. Under normal conditions we cannot hear our heartbeat, blood flow or the rumbling of our digestive system – only in extreme silence (inside a special anechoic chamber) can one hear the “symphony” of one’s own organs. As one tester described it, “when you stop breathing you can hear your heart beating and the blood flowing through your veins”. But in everyday life these sounds are effectively muffled by layers of tissue, fat and fluid.

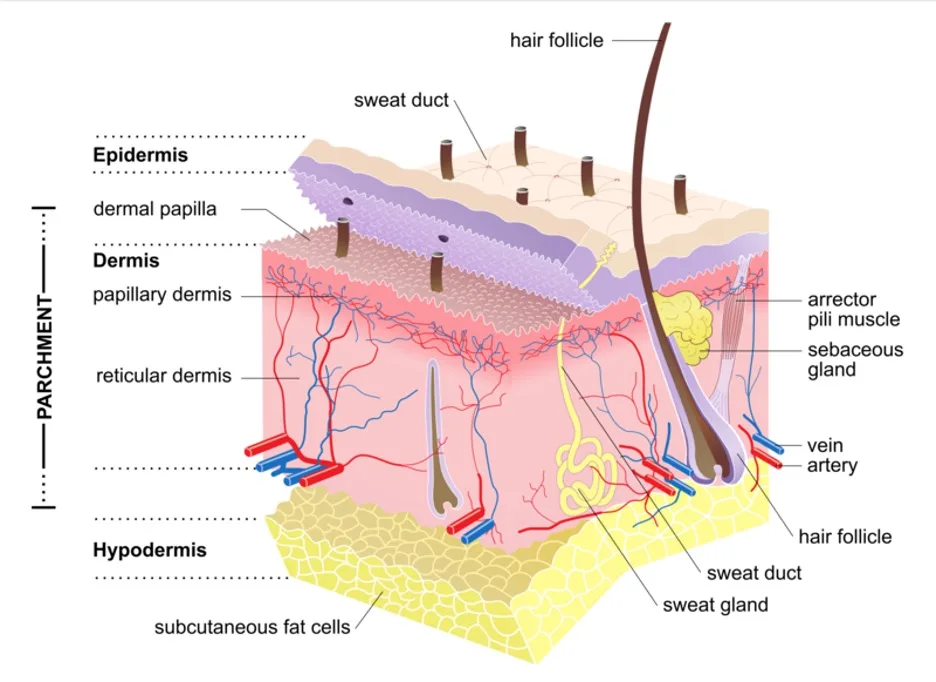

While soft tissues and fluids strongly absorb and dissipate vibrations, our rib cage and skull form hard shells that reflect and block sound (in fact, ultrasound imaging experts note that fat tissue causes a very high attenuation of sound waves). In effect, the body’s “acoustic engineering” prevents internal sounds from becoming an auditory distraction – a kind of built-in sound insulation.

These biological strategies suggest analogies for architecture: We can hide and cushion noise sources, build layered material assemblies, and separate structure and space – just as the body isolates organs from our ears.

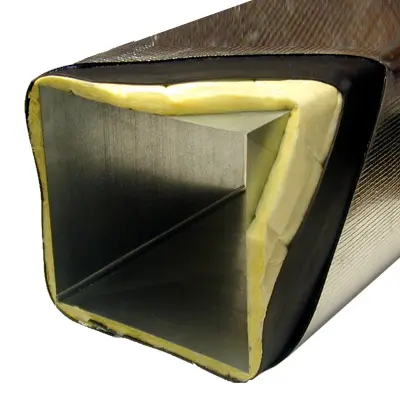

Just as organs are lined with fluid- and oil-filled cavities, architects “hide” mechanical equipment inside acoustically treated chambers or ducts. Large machinery and HVAC systems are often placed in isolated mechanical floors or sound-absorbing enclosures, and silencers or attenuators are installed in ducts and pipes to control vibration.

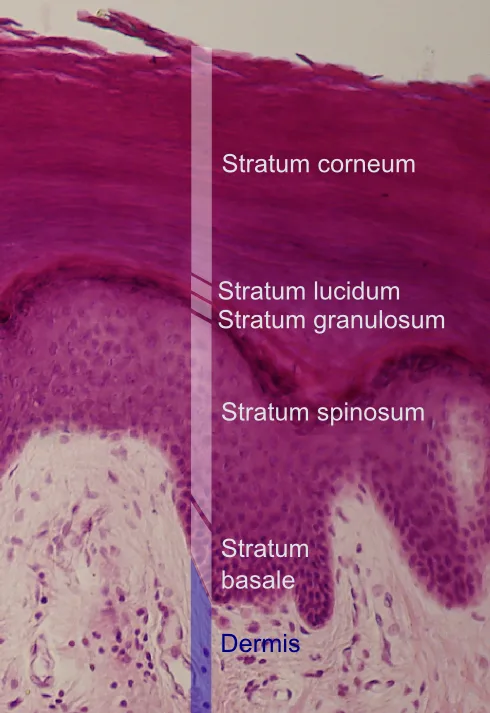

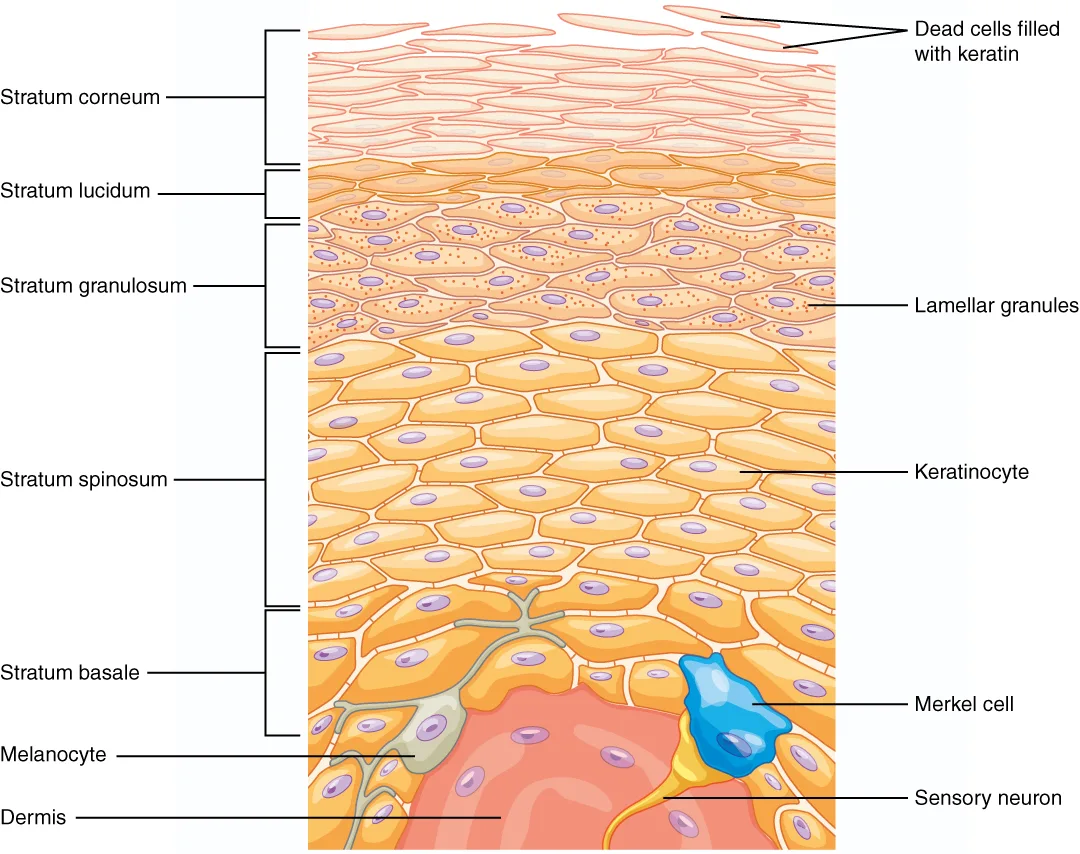

Similarly, the body’s multilayered structure (skin-fat-muscle-bone) inspires multilayer wall assemblies: a cladding layer, an insulating “fat” cavity and a rigid “bone” structure. Mass-spring-mass structures with insulation between them can significantly increase sound insulation.

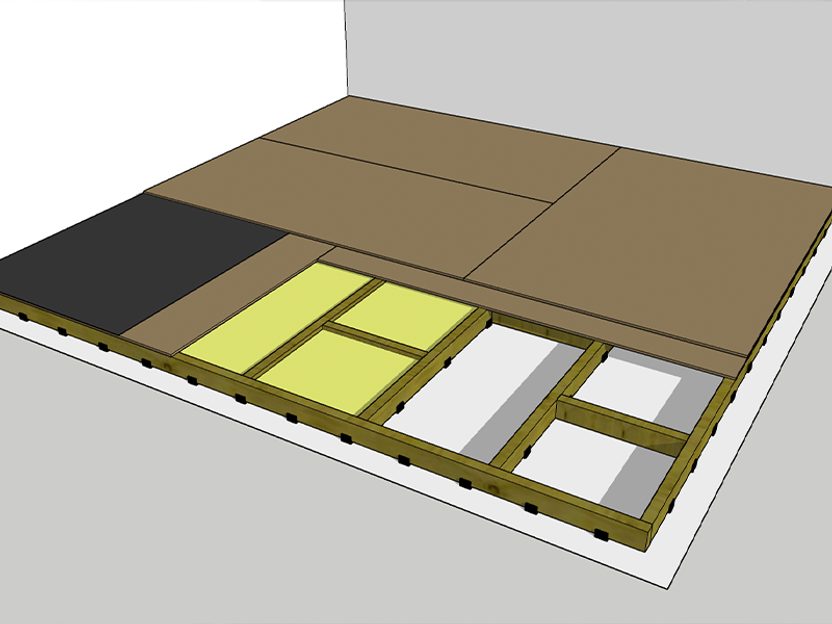

Regulations use STC (Sound Transmission Class) ratings to measure this. To raise the STC, assemblies typically add extra mass, insulation or flexible breaks between layers. This is similar to adding damping tissue between rigid elements. Finally, the skeleton of the body is effectively separated from the soft tissues by joints and padding, just as floating floors or flexible ducts separate the structural skeleton of a building from the finished surfaces.

Floating floors (structural plates supported on flexible pads) can significantly reduce impact noise from the floor by greatly improving transmission loss. Similarly, flexible metal ducts (thin framing strips) isolate drywall from studs, disrupting the direct sound path and improving wall STC. Even a subway engineer uses the same idea: floating floor track bearings (concrete slabs on rubber springs) effectively break the chain of vibration from train wheels to the ground, “similar to inertial bases on springs used to support stationary machinery”.

Architectural Analogues of Biological Insulation

- Hiding noise sources (organ analogs): Mechanical cabinets and buckets act like body cavities around the equipment. A furnace or pump is placed in a fully lined room with acoustic blankets on the walls and its noise can be isolated by the enclosure (similar to an organ inside a fluid sac). Internal silencers or external windings of sound-absorbing material are installed in the ducts to reduce fan noise.

- Layered partitions (leather-oil-muscle): A classic strategy is a multi-layered wall: an outer skin, an air/insulation cavity and an inner skin. This reflects skin (outer), fat/muscle (insulation) and bone (structure). The gaps are filled with fibrous insulation (e.g. mineral wool) that absorbs sound like fatty tissue. Rock wool insulation is famous for blocking and absorbing sound while dampening vibration. Such layers create a mass-spring-mass effect: each dense layer adds mass (blocks low frequencies) and each soft layer adds damping (absorbs mid/high frequencies). In practice, insulated double batten walls or double-layer drywall (usually on flexible clips) are used to achieve high STC ratings. Balancing seams and sealing gaps ensures that there are no direct “acoustic shortcuts”, just as balancing fat and tissue channels prevents direct sound leakage.

- Discrete structure (skeletal analogy): The bones of the body provide structure while minimizing noise transmission from muscle movements. Similarly in buildings, we separate (isolate) structural elements from occupied spaces. Floating floors on neoprene pads or spring isolators reduce vibration transmission by eliminating direct hard contact. In walls or ceilings, flexible channels act as small springs: the rigid connection with studs is broken by hanging plasterboard over them. This “cuts the path” of sound waves, so less vibration energy passes through. Even in heavy construction, floor isolators under all rooms or equipment act like cushioned joints, preventing machine noise or footsteps from shaking the entire frame.

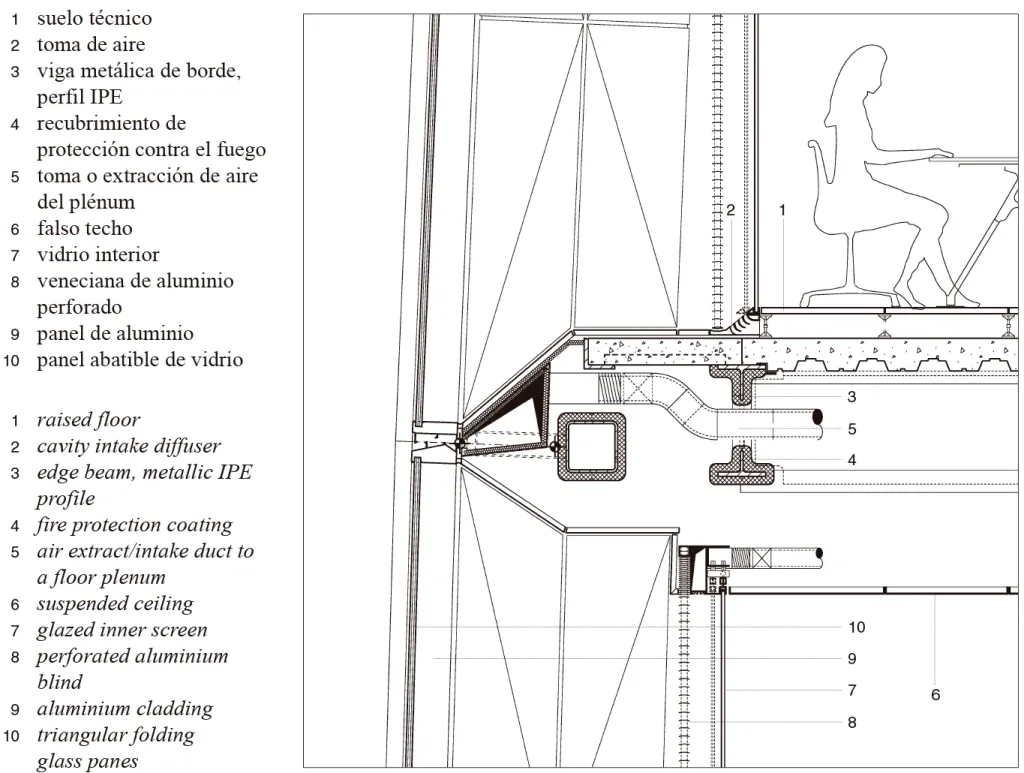

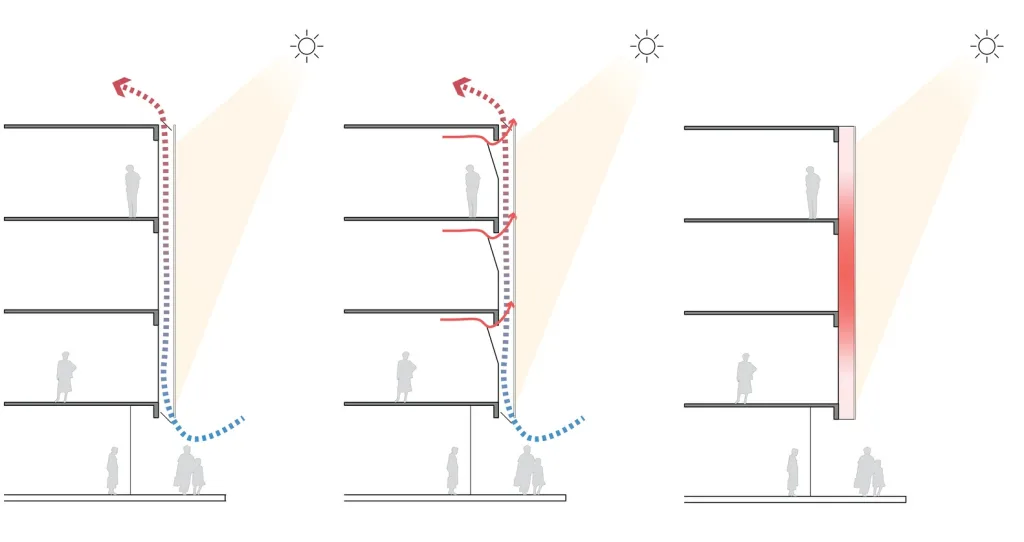

- Air/liquid buffer zones (membrane analogy): Just as air-filled cavities and membranes in the body buffer organs (such as cranial sinuses or lung air cavities), buildings can use air cavities or cavities to protect sound. A prominent example is the double skin facade: two glazed walls separated by a ventilated cavity. This air buffer reduces both heat and noise from outside. Research states that the double-walled interstitial space “acts as insulation against excessive… sound and improves the auditory comfort of the building”. On a smaller scale, even simple stepped or recessed walls (with offset courses or air gaps) act as acoustic labyrinths, preventing straight-line transmission of sound. Like a fluid layer that reflects or absorbs internal sounds, these voids trap or detone sound energy.

Application and Examples

These strategies are widely used in construction. Floating floorsare common in recording studios where a gypsum subfloor on rubber pads provides a “dead” floor with much higher impact isolation. Flexible duct walls are common in hotels and apartment buildings; a test rig has shown that adding a layer of duct can increase wall STC by ~5 points.

For more explanation about Floating Floors, see this article: https://auralex.com/blog/sound-isolation-basics-how-to-build-a-floating-floor/

In HVAC design, duct silencers (attenuators) filled with fibrous media or micro-perforated panels are installed sequentially, similar to the fluid damping noise of an organ. Acoustic doors and vestibules act like joint capsules or sound locks, creating a transition space to block direct transmission.

A sophisticated example is the double skin facade. The famous 30 St Mary Axe (“Gherkin”) in London uses a ventilated double shell to stabilize the temperature and buffer noise from the street. Here the air gap, which can also be controlled mechanically, reduces the penetration of external noise, just as a sinus cavity silences a blow to the head.

In transit projects, floating slab rail beds are used in subways around the world. By supporting the rails on elastomeric pads, an exact analog of suspending a machine base on springs, engineers have significantly reduced ground-borne noise in nearby hospitals and schools.

Source: https://www.archdaily.com/922897/how-do-double-skin-facades-work

In all these cases, designers also manage side paths: each entrance is acoustically isolated, electrical boxes are staggered, and side walls are filled with insulation – mimicking the body’s tendency to route noise through complex pathways rather than passing it directly. The source-path-receiver model in acoustics (sound absorbs at the source, attenuates on the path, then absorbs at the receiver) represents the same principle as a nervous system filtering its own noise.

Guidance for Noisy Building Types

For architects and engineers working on noisy typologies (dense housing, hospitals, schools, transit centers), these biomimetic insights guide practical choices:

- Locate and enclose sources: Locate noisy equipment (generators, boilers, kitchens) in dedicated, enclosed spaces. Use acoustic plenum enclosures for ducts and locate noisy rooms away from quiet zones (imagine a heart tucked deep in the chest, away from sensitive lungs).

- Layer partitions: Specify wall and floor assemblies with extra mass and insulation. Hospitals typically require minimum degrees of separation – FGI guidelines require at least 45 STC (50 STC for high privacy) between patient rooms. Achieving these values typically requires floor-to-floor concrete walls with cavity insulation and double layers of plaster (high STC). In apartments, adding a second row of studs or flexible clips are solutions to prevent footsteps from being heard from the floor above.

- Decouple the structure: Use floating floor coverings (concrete on neoprene pads) in gyms, libraries or bedrooms above noisy areas. Hang flexible hangers in corridors to isolate ceilings from service floors above. Plumbing can be mounted on isolation brackets. These measures mimic the way joints allow the body to move by preventing bones from hitting each other.

- Buffer with air and absorption: Add air gaps and absorptive volumes wherever possible. In courtyards or atriums adjacent to roads, use thick planting or water features (sound-absorbing landscaping) as acoustic membranes. Inside schools, use acoustic ceilings and wall panels (usually mineral wool or foam) to absorb reverberant noise. Such materials both absorb echoes and trap airborne noise, like fatty tissue in the body.

- Seal and stagger: Carefully fill gaps, acoustically seal floor-wall joints and design offset geometry. A “sound lock vestibule” placed between the corridor and the classroom – similar to a joint capsule or eardrum – prevents direct sound leakage. Similarly, in hospitals, bathrooms or closets are placed between rooms to buffer noise between rooms.

Architects should treat buildings as living organisms – with different layers, protective cavities and isolated organs – to create quiet, comfortable interiors. Quiet hospitals help patients recover, well-implemented classroom acoustics improve learning and focus, and peaceful quiet housing enhances occupants’ well-being. As research confirms, “noise can affect cognitive processing, mental health and motivation“.

In short, applying the body’s inner silence to buildings is not just a process to isolate sound. It improves the clarity and comfort of the living space.

Sources:

- Chen, Y., Zhang, Y., Wang, Y., & Zhang, Y. 2022. “Acoustic Attenuation and Dispersion in Fatty Tissues and Tissue-Mimicking Phantoms.” Frontiers in Bioengineering and Biotechnology 10: 983577. https://pmc.ncbi.nlm.nih.gov/articles/PMC9835773/

- Auralex Acoustics. 2023. “Sound Isolation Basics: How to Build a ‘Floating’ Floor.” Auralex Acoustics. https://auralex.com/blog/sound-isolation-basics-how-to-build-a-floating-floor/.

- Gray, Richard. 2017. “Inside the Quietest Place on Earth.” BBC Future, May 29, 2017. https://www.bbc.com/future/article/20170526-inside-the-quietest-place-on-earth.

- Kerner, Michael C. 2012. “Ensuring Acoustical Performance with Resilient Channels.” Construction Specifier, July 2012. https://www.clarkdietrich.com/sites/default/files/imce/pdf/Articles/10-18-12_RC-Delux/CD_ConstructionSpecifier-Acoustical_Performance_with_RC_%20July-2012.pdf.

- Rockwool. 2019. “Fundamentals of Architectural Acoustics.” Rockwool Blog, August 15, 2019. https://www.rockwool.com/north-america/advice-and-inspiration/blog/fundamentals-of-architectural-acoustics/.

Discover more from Dök Architecture

Subscribe to get the latest posts sent to your email.